Virtual Vibration Testing

main parametersVirtual Vibration Testing

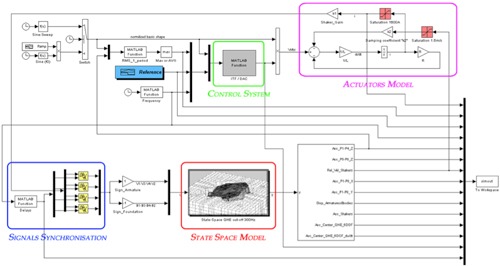

“Virtual Testing” has become in recent years more and more a common topic in the world of environmental testing. For vibration testing, it helps identifying critical aspects such as facility performance issues and Eigen frequency shifts with respect to cantilever predictions before the test takes place.

The main advantages are:

Predict test facility performance before the test campaign

Assess frequency shift of main modes due to coupling with the facility with respect to cantilever boundary condition predictions

Assess notching profiles behaviour before the test campaign

Optimize control parameters such as compression factor or pilot placement before the test to achieve optimal performance

Aid in correlating the spacecraft FEM post test

Available validated simulation platforms are available for the HYDRA vibration facility and QUAD shaker.